Microtechnology

Microfluidic lab-on-a-chip

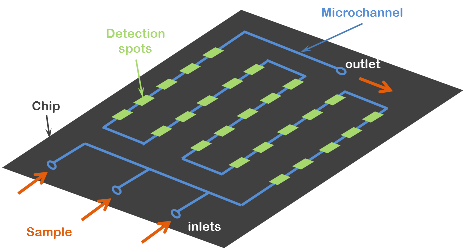

MicroBioMed project aims at developing a lab-on-a-chip demonstrator for the immunological detection of human diseases (in vitro diagnosis). To achieve this goal, fluidic components of micrometer size must be developed, which means dealing with microfluidics.

Microfluidic chip

A microfluidic chip is a set of micro-channels connected together and trapped into a chip. Connection to injection and instrumentation components is made through inlets and outlets pierced through the chip.

Materials

Most commonly used materials for lab-on-a-chips are silicon, glass and polymers (such as PDMS).

![]()

Materials’ choice is critical because of its impact on fabrication processes but also on many parameters such as the possible geometries, the assembly easiness, the temperature stability, the optical transparency, etc.

Fabrication processes

Depending on the material, different fabrication methods can be used for microfluidic chips:

- silicon microfabrication: wet etching, dry etching…

- glass microfabrication: wet etching, powder blasting…

- photostructuring: stereolithography, laser ablation…

- polymer replication techniques: injection molding, hot embossing…

After the microstructuring process, back-end process steps are usually necessary to get a fully functional microsystem. Frequent steps are: joining, metallization, cutting, surface modification, heterogeneous integration and quality control.

Application fields

- Life sciences analytical science: biotechnology, diagnosis, analytical chemistry, medical technology, environmental monitoring, food analysis

- Chemistry: chemistry, pharmacy, cosmetics, fuel cells

- Fluid handling: mechanical engineering, optical industry, electronic industry, print industry, textile industry, industrial automation

Use of lab-on-a-chip in medicine is one of the main applications of microfluidic devices to perform several medical tests on a single chip. Current developments focus especially on point-of-care diagnosis and on diagnostic tools for personalized medicine.

Advantages:

- Reduction of analysis times

- Reduction of sample volumes

- Increased performance

- Simpler handling of complex tasks

- Portable systems for on-site analyses

Challenges:

- Functional integration in the chip

- Low-cost and easy-to-manufacture devices

- Market acceptance

- Regulatory aspects (ISO norms, reimbursement…)